Top10 considerations when validating an autoclave

驗(yàn)證高壓滅菌器時的十大注意事項(xiàng)

Consideration 1 Choosing the right sterilisation cycle to implement

注意事項(xiàng)1:選擇正確的滅菌周期

There are three basic types of sterilisation cycles.Choose the right one according to the type of goods to be sterilised:

滅菌周期有三種基本類型。根據(jù)需要滅菌的物品類型選擇合適的滅菌周期:

Hard Goods(Vacuum)

1、硬質(zhì)物品(真空)

Suitable for items that are easy to sterilise,because air removal and steam penetration are highly effective on these items.e.g.,open glassware and large diameter piping

適用于易于滅菌的物品,因?yàn)榭諝馀懦驼羝麧B透對這些物品非常有效,例如開放式玻璃器皿和大直徑管道。

A typical hard goods cycle may draw one vacuum prior to introducing steam to reach the desired sterilisation temperature.

典型的硬質(zhì)物品循環(huán)在引入蒸汽之前可能會抽一次真空,以達(dá)到所需的滅菌溫度。

Wrapped Goods(Vacuum)

2、包裝貨物(真空)

Utilized for items that are difficult to sterilise,because air removal and steam penetration are harder to achieve on these items than on hard goods.

用于難以消毒的物品,因?yàn)榕c硬質(zhì)物品相比,這些物品更難排出空氣和滲透蒸汽。

e.g.,empty bottles(glass or plastic)with lids,gowns,long hoses/tubes,vent filters,portable vessels with small inlet/outlet ports

例如:帶蓋的空瓶(玻璃瓶或塑料瓶)、防護(hù)服、長軟管/管子、通風(fēng)過濾器、帶小入口/出口的便攜式器皿

A typical wrapped goods cycle may draw three or more vacuums prior to reaching sterilisation.A post-sterilisation vacuum draws the steam from the load items.

在滅菌之前,一個典型的包裝物品循環(huán)可能要抽三次或更多次真空。滅菌后的真空將蒸汽從裝載物品中抽出。

Liquids(Non-vacuum)

3、液體(非真空)

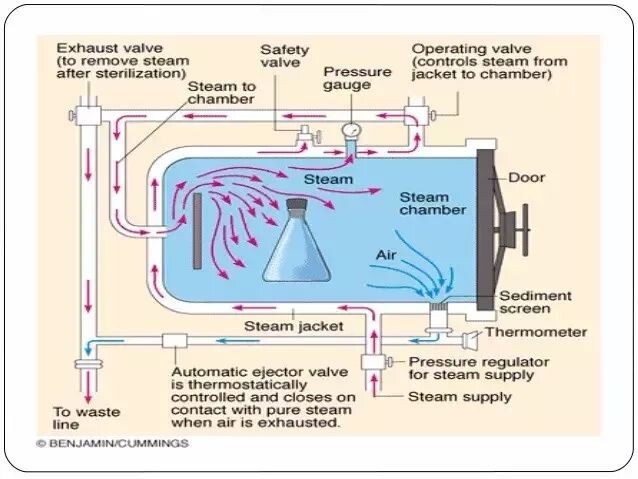

Items that contain liquids generally cannot have a deep vacuum pulled or the liquid will be drawn out of them.Autoclave cycles for liquids generally heat up and cool down without a vacuum.Steam,introduced into the top of the chamber,displaces the air.The air is pushed to the bottom of the chamber and is removed.

含有液體的物品一般不能抽成很深的真空,否則液體會被抽出。液體高壓滅菌器的加熱和冷卻循環(huán)一般不抽真空。蒸汽被引入腔室頂部,取代空氣。空氣被推到腔室底部并被排出。

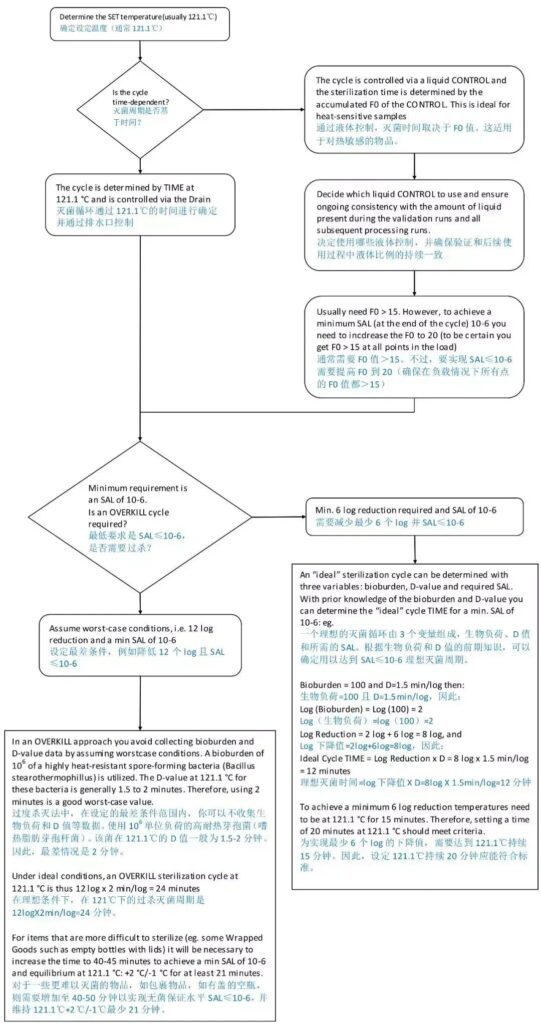

The steps involved in choosing the right sterilisation cycle.

選擇正確滅菌周期的步驟:

Consideration 2 Which load configurations to use?

注意事項(xiàng)2:使用哪種負(fù)載配置?

A variable to consider is whether to use fixed load or variable load configurations.There’s a trade-off here between validation effort and operational flexibility–do you want to validate a wide range of load configurations to increase Production’s flexibility in loading the autoclave?Here are some typical load configurations to consider:

需要考慮的一個變量是使用固定負(fù)載還是可變負(fù)載配置。這需要在驗(yàn)證工作和操作靈活性之間權(quán)衡--您是否希望驗(yàn)證多種負(fù)載配置,以提高生產(chǎn)部門在高壓釜負(fù)載方面的靈活性?以下是一些需要考慮的典型負(fù)載配置:

A fixed load/fixed position configuration means that any load to be sterilised will be placed inside the chamber in exactly the same way for every processing run.A diagram of the load configuration should appear in the Standard Operating Procedure(SOP)so that operators can reproduce the load for every processing run.This situation requires the fewest validation runs(3),but offers no flexibility in load configurations.

固定負(fù)載/固定位置配置是指在每次處理過程中,要滅菌的負(fù)載都將以完全相同的方式放置在滅菌室內(nèi)。標(biāo)準(zhǔn)操作程序(SOP)中應(yīng)包含負(fù)載配置圖,以便操作員在每次處理運(yùn)行時都能復(fù)制負(fù)載。這種情況需要的驗(yàn)證運(yùn)行次數(shù)最少(3次),但負(fù)載配置沒有靈活性。

A fixed load/variable position configuration means that the location of the load items in the autoclave can vary.Only a list of the items that can be in a load is required for the SOP.The validation runs must demonstrate positional equivalence by rotating the items from location to location during the test runs.If positional equivalence is proven after three validation runs,then you can stop.A fixed load/variable position configuration gives operators flexibility in loading the autoclave.This saves time when loading large loads of numerous items of different types.

固定負(fù)載/可變位置配置意味著負(fù)載物品在高壓滅菌器中的位置可以變化。SOP只要求列出負(fù)載中的物品清單。驗(yàn)證運(yùn)行必須通過在測試運(yùn)行期間將物品從一個位置旋轉(zhuǎn)到另一個位置來證明位置等同。如果三次驗(yàn)證運(yùn)行后證明位置等效,則可以停止。固定裝載/可變位置配置為操作員裝載高壓滅菌器提供了靈活性。當(dāng)裝載大量不同類型的物品時,可以節(jié)省時間。

A variable load configuration means that different combinations of items and/or numbers of any item(s)can be placed into the chamber.The validation runs must demonstrate that the cycle is adequate for both a maximum and minimum load configuration.The minimum load tests are done with only one item in the autoclave,that item being the load item demonstrated as being the most difficult to sterilise.

可變負(fù)載配置是指可將不同的物品組合和/或任何物品的數(shù)量放入腔體內(nèi)。驗(yàn)證運(yùn)行必須證明,循環(huán)足以滿足最大和最小負(fù)載配置的要求。最小負(fù)載測試是在高壓滅菌器中只放入一個物品的情況下進(jìn)行的,該物品是經(jīng)證明最難滅菌的負(fù)載物品。

Consideration 3 Choosing the right Control for liquid cycles

注意事項(xiàng)3:為液體循環(huán)選擇合適的控制裝置

The choice of the Control used when sterilising liquids determines whether the load you are sterilising will pass all the acceptance criteria.

液體滅菌時使用的控制裝置的選擇決定了滅菌負(fù)載是否能通過所有驗(yàn)收標(biāo)準(zhǔn)。

More than one liquid Control may be needed to validate all the different types of bottles and liquids requiring sterilisation.Consider the following when choosing the Control for liquid cycles:

可能需要一個以上的液體控制裝置來驗(yàn)證需要滅菌的所有不同類型的瓶子和液體。為液體循環(huán)選擇控制裝置時應(yīng)考慮以下因素:

The size of the bottle and its fill volume–the larger the bottle and the greater its volume,the harder it is to sterilise.瓶子的大小和填充量-瓶子越大其體積越大,就越難滅菌。

The thickness of the glass–thicker glass is more difficult to sterilise than thinner glass.玻璃的厚度,厚玻璃比薄玻璃難滅菌

The viscosity of the liquid–the greater the viscosity,the slower the heat-up time,and the harder it is to sterilise.液體的粘度–粘度越大傳熱越慢,就越難滅菌。

The liquid Control will ideally be the one that is the most difficult to sterilise(worst-case)and will be located at the coldest spot in the chamber(lower level near the front door or directly above the drain).

理想情況下,液體控制裝置是最難消毒的裝置(最壞情況),并位于箱體內(nèi)最冷的位置(靠近前門的低層或下水道的正上方)。

Don’t be tempted to use a Control that is dramatically different from the composition of the load.If the liquid Control takes too long to reach the sterilisation temperature,then the protein composition of the media in the rest of the load(which may have exceeded the desired temperature by the time the Control reaches the sterilisation temperature)may be denatured.

不要輕易使用與負(fù)載成分大相徑庭的對照品。如果液體控制劑達(dá)到滅菌溫度的時間過長,那么負(fù)載中其他培養(yǎng)基的蛋白質(zhì)成分(在控制劑達(dá)到滅菌溫度時可能已超過所需溫度)可能會變性。

If in doubt,perform preliminary studies using different liquid Controls to obtain information on the load's heat-up times and F0-values.

如有疑問,請使用不同的液體控制裝置進(jìn)行初步研究,以獲得有關(guān)負(fù)載加熱時間和F0值的信息。

The number of validation runs required for different types of liquids and bottles can be reduced by grouping liquids with similar viscosities,bottle sizes and fill volumes.Each liquid Control will have a unique maximum and minimum load configuration associated with it.

通過將粘度、瓶子大小和灌裝量相似的液體分組,可以減少不同類型液體和瓶子所需的驗(yàn)證運(yùn)行次數(shù)。每種液體控制都有其獨(dú)特的最大和最小負(fù)載配置。

Use procedural controls to ensure that the choice of liquid,bottle size and fill volume used for each Control,and its location in the chamber,are maintained during the validation runs and subsequent processing runs.

使用程序控制,確保在驗(yàn)證運(yùn)行和后續(xù)處理運(yùn)行期間,保持每個"控制"所用的液體選擇、瓶子大小和填充量,以及在腔體內(nèi)的位置。

Consideration 4 Determining which load items are the most difficult to sterilise and which location(s)within the items represents the worst-case conditions

注意事項(xiàng)4:確定哪些裝載物品最難滅菌,以及物品中哪個(些)位置代表最惡劣的條件

With a large load containing a wide variety of different types of items,the number of possible test locations within items seems to approach infinity.It also can be difficult to get the thermocouple and indicators(BI&CI)into the item without affecting the item’s ability to be sterilised and/or ruining the item(a concern with expensive items).

由于裝載的物品種類繁多,物品內(nèi)可能的測試位置似乎無窮無盡。此外,要將熱電偶和指示器(BI和CI)放入物品中而不影響物品的消毒能力和/或毀壞物品(這是昂貴物品的一個問題)也很困難。

We must evaluate each item on a case-by-case basis and determine how to best challenge the item.Often the item must be sealed somehow to return it to a state that represents equivalency with respect to steam penetration.

我們必須根據(jù)具體情況對每件物品進(jìn)行評估,并確定如何以最佳方式對物品提出質(zhì)疑。通常情況下,必須以某種方式對物品進(jìn)行密封,使其恢復(fù)到與蒸汽滲透等效的狀態(tài)。

Some examples:

舉例:

Q.What is the most difficult point to sterilise in a hose of uniform diameter?

問:一個直徑均一的軟管內(nèi)哪一點(diǎn)最難滅菌?

A.In the centre of the length of hose.

答:在軟管長度的中心。

Q.How do you get a 3 m length of thermocouple into the middle of a 20 m hose?

問:如何將一個3米長的熱電偶插入20米的軟管中間?

A.在軟管中間開一個槽,然后將熱電偶從槽中插入,確保用硅膠密封槽口。如果不密封,就無法正常挑戰(zhàn)軟管。或者,找兩根10米長的軟管(如果有的話),將熱電偶插入接頭后,用連接器將它們連接起來。使用這種方法不會損壞20米長的軟管。

答:在軟管中間刻一插槽,熱電偶沿著插槽插入軟管,確保用硅膠將插槽密封,如果你沒有密封,則不能挑戰(zhàn)軟管。或者,將兩個10米的軟管(如有)插入熱電偶后用連接器將其連接,用這種方法則不用破壞20米長的管子。

Q.What is the worst-case location within a bottle,flask or cylinder?

問:瓶子、錐形瓶和柱形瓶那個位置最難滅菌?

A.In the centre near the bottom(but not touching the floor).

答:在靠近底部的中間(但不接觸底面)。

Q.How do you hold a thermocouple in position inside a sealed bottle?

問:如何保持熱電偶在一個密封瓶子里的位置?

A.Choose a piece of Silastic tubing with an internal diameter(ID)that is narrow enough to hold the thermocouple probe without letting it slip through.Drill a hole in the bottle's lid the same size as the outer diameter(OD)of the tubing.Push the tubing through the hole,into the bottle.Now push the probe into the tubing.Slide the probe through the tubing until it reaches the desired position in the bottle.Make sure it is not touching the wall of the bottle.For bottles with rubber stoppers,make a small hole in the centre of the stopper,sufficient to push the thermocouple through.

答:選擇一個內(nèi)徑與熱電偶探頭相近的硅橡膠管件套住它以確保不會滑落。在瓶蓋上鉆一個和管子外徑一樣大的孔。通過孔將管子插入瓶中。將探頭推入管子中,推動探頭直至到達(dá)瓶子中所需位置。確保它不會觸碰瓶壁。對于橡膠瓶塞的瓶子,在篩子中間鉆一個小孔,足以使熱電偶通過。

Consideration 5 Wired temperature thermocouples are cumbersome and don’t always give accurate data

注意事項(xiàng)5:有線熱電偶較復(fù)雜,且并非總是提供準(zhǔn)確的數(shù)據(jù)

The list below highlights some considerations when using wired thermocouples:

下面重點(diǎn)介紹一些使用熱電偶傳感器時的注意事項(xiàng):

Some loss of steam(leakage)will occur when the wire's outer plastic protector has been cut and air or steam can pass through it.This may result in a failed leak test.當(dāng)導(dǎo)線的外層塑料保護(hù)膜被切割并且有空氣或蒸汽通過,就會發(fā)生一些蒸汽損耗(泄漏),可能會導(dǎo)致泄漏測試失敗。

Validator thermocouples inside the chamber will draw condensate and will need a slice/cut made in their outer protective layer,to ensure that any fluid is released.If condensate passes through the wires and into the electronics,the thermocouples will be destroyed.在腔室內(nèi)的熱電偶會吸冷凝水,需要在腔室外部將熱電偶保護(hù)層切開以將冷凝水釋放。如冷凝水通過熱電偶流到驗(yàn)證儀電子元件,熱電偶將損壞。

The thermocouple may be difficult to place into the item without adversely affecting the item’s ability to be sterilised and/or ruining the item(a concern with expensive items).熱電偶可能難以在不影響物品滅菌和/或破壞物品(貴重物品)的情況下,放入物品中。

Wires can get caught(and be damaged)under the autoclave's wheels when moving loads into and out of the chamber.當(dāng)進(jìn)料或出料時熱電偶可能被高壓滅菌器的輪子卡住(并損壞)

It is difficult to place wires inside sealed bottles without(i)touching the inside wall,and(ii)compromising the bottle’s ability to be sterilised.將熱電偶裝在密封瓶里并且不碰到內(nèi)壁是很難做到的,并且降低瓶子的無菌程度。

You may be limited by the number of wires you can place through the autoclave's inlet.你可能會受限于高溫滅菌器進(jìn)口的導(dǎo)線數(shù)量。

The resistance of the thermocouple in some locations in the chamber can change,leading to inaccurate and/or unreliable data even though the pre/post calibration verifications meet specifications.

即使前/后校準(zhǔn)確認(rèn)符合標(biāo)準(zhǔn),某些位置熱電偶電阻也會發(fā)生變化,從而導(dǎo)致數(shù)據(jù)不準(zhǔn)確和/或不可靠。

Case Study

示例

This example looks at nine thermocouples placed into a loaded chamber.They were evenly spaced from one another at the top,middle and bottom levels and at the front,centre and rear of the chamber.

此示例包含裝載腔室內(nèi)的9個熱電偶。他們均勻分布在頂部,中部和底部,以及前、中、后部。

The study used wired thermocouples in a loaded chamber for a 40-minute cycle at 121.1°C.The chamber's maximum pressure of 2.16 bar(at any time)was equivalent to 122.7°C.One probe(top front LHS)constantly reached temperatures between 123.3°C and 123.5°C.All other probes were within the required limit of 120.1°C+2°C/-1°C at temperatures from 122.4°C to 122.7°C.

該研究使用有線熱電偶用于測試121.1℃40分鐘的負(fù)載腔體。內(nèi)室最大壓力2.16bar(在任何時間)相當(dāng)于122.7℃。一個探頭(頂部前左)溫度持續(xù)維持在123.3°C-123.5°C之間。所有其他探頭則在規(guī)定溫度范圍120.1℃+2°C/-1°C內(nèi),在122.4°C至122.7°C之間

The temperature differential started during heat-up and remained during the sterilisation and post vacuum cooling phases.The Equipment Engineer and the Manufacturer agreed that the temperature reading at this position was inaccurate and unreliable.The thermocouple reading was inconsistent with the steam pressure indication and the other thermocouple readings.Consequently,no useful data were collected at that point.

溫差始于加熱階段,并在滅菌和真空冷卻后階段保持不變。設(shè)備工程師和制造商一致認(rèn)為,該位置的溫度讀數(shù)不準(zhǔn)確、不可靠。熱電偶讀數(shù)與蒸汽壓力指示和其他熱電偶讀數(shù)不一致。因此,在該位置沒有收集到有用的數(shù)據(jù)。

Consideration 6 Determining the acceptance criteria

注意事項(xiàng)6:確定驗(yàn)收標(biāo)準(zhǔn)

An example:

一個例子:

You run your validation studies,only to realise that you cannot meet one of the acceptance criteria.But,was it really needed in the first place?

您進(jìn)行了驗(yàn)證研究,卻發(fā)現(xiàn)自己無法滿足其中一項(xiàng)驗(yàn)收標(biāo)準(zhǔn)。但是,一開始真的需要這樣做嗎?

It’s important to understand the aim of the autoclave cycle and what its parameters are.For example,is it for sterilisation or decontamination?Is the load heat sensitive,or can it be subjected to an overkill cycle?Is it a porous load(hard/wrapped goods),or is it a liquid?

了解高壓滅菌器循環(huán)的目的及其參數(shù)非常重要。例如,是用于滅菌還是去污?裝載的是熱敏性貨物,還是可以進(jìn)行過度殺菌循環(huán)?是多孔負(fù)載(硬質(zhì)/包裹貨物),還是液體?

Most Validation departments have a Standard Operating Procedure(SOP)detailing the validation requirements for sterilisation processes.Included in that is a complete list of all the acceptance criteria.

大多數(shù)驗(yàn)證部門都有一個標(biāo)準(zhǔn)操作程序(SOP),詳細(xì)說明滅菌過程的驗(yàn)證要求。其中包括所有驗(yàn)收標(biāo)準(zhǔn)的完整清單。

Each phase of the autoclave cycle is likely to have different acceptance criteria:

滅菌柜不同階段的循環(huán)周期存在不同的遵循標(biāo)準(zhǔn):

Phase I–Heat distribution(empty chamber)

第一階段-熱分布(空載)

Phase II–Heat distribution(loaded)

第二階段-熱分布(裝載)

Phase III–Heat distribution(loaded)cold spot determination within

第三階段-熱分布(裝載)內(nèi)部冷點(diǎn)測定

Phase IV–Heat penetration

第四階段-熱穿透

There may also be different requirements for Phases III and IV if you are sterilising liquids(non-vacuum)vs.porous items(vacuum),e.g.,F0>15 at the end of sterilisation(liquids only).

如果是對液體(非真空)和多孔物品(真空)進(jìn)行滅菌,則第三和第四階段的要求也可能不同,例如,滅菌結(jié)束時F0>15(僅限液體)。

Typical acceptance criteria are as follows:

典型的驗(yàn)收標(biāo)準(zhǔn)如下:

All porous cycles require min SAL 10-6 at the end of sterilisation.All porous items are subject to at least one post-vacuum cycle which removes steam from the chamber(Phases III&IV).所有多孔循環(huán)在滅菌結(jié)束時都需要最小SAL 10-6。所有多孔物品都至少要進(jìn)行一次真空后循環(huán),以去除滅菌室中的蒸汽(第三和第四階段)。

All liquid cycles require a min SAL 10-6 and a min F0>15 at the end of the cycle,because they do not use vacuum and are subject to natural cooling?(Phases III&IV).所有液體循環(huán)都要求在循環(huán)結(jié)束時達(dá)到最小SAL 10-6,最小F0>15,因?yàn)樗鼈儾皇褂谜婵眨⑹艿阶匀焕鋮s?(第三和第四階段)。

Throughout the sterilisation phase all temperatures are within a 3°C range(Phases II,III&IV)?,e.g.,121.1°C-1°C/+2°C.在整個滅菌階段,所有溫度都在3°C范圍內(nèi)(第二、第三和第四階段)?,例如,121.1°C-1°C/+2°C。

Throughout the sterilisation phase all temperatures in the chamber are within 1.0°C of the chamber's mean temperature(Phase II).在整個滅菌階段,滅菌室內(nèi)的所有溫度都保持在滅菌室平均溫度的1.0°C以內(nèi)(第二階段)。

The steam's temperature corresponds to its vapour pressure(Phases II,III&IV).4蒸汽的溫度與其蒸氣壓力相適應(yīng)(階段II,III及IV)。

Timed measurements are to be controlled to an accuracy of±1%.?時間計(jì)時控制在±1%的精度范圍內(nèi)(階段II,III及IV)。

Required pre-certification and post-certification of the data logger ensures that the temperature measurement system is accurate to within±0.5°C.驗(yàn)證前和驗(yàn)證后溫度測量系統(tǒng)的準(zhǔn)確度在±0.5℃的范圍內(nèi)。

The load is visually dry at the end of the cycle(porous cycles only).滅菌結(jié)束時裝載目測干燥(只針對多孔裝載)。

All autoclaved Biological Indicators(BIs)are negative and the control is positive following incubation(Phase IV).所有生物指示劑培養(yǎng)結(jié)果陰性,陽性對照陽性(階段IV)。

Consideration 7 Adequately documenting the validation test runs

注意事項(xiàng)7:充分記錄驗(yàn)證測試運(yùn)行情況

Documenting what was done during the validation test runs is all about knowing what needs to be documented and how to present it.This documentation must be clear,consistent between runs and transparent,and must conform to all GMP requirements.It must be complete and must include the following items:

記錄驗(yàn)證測試運(yùn)行期間所做的工作,關(guān)鍵在于了解需要記錄什么以及如何進(jìn)行記錄。這種記錄必須清晰,在不同的試運(yùn)行之間保持一致和透明,并且必須符合所有GMP要求。文件必須完整,必須包括以下項(xiàng)目:

a diagram showing the location of all load items within the autoclave chamber顯示高壓滅菌腔室內(nèi)所有裝載物品位置的圖表

the precise location/number of each thermocouple,BI and CI within each item各熱電偶、BI、CI的數(shù)目和精確位置

the printout from the data recorder數(shù)據(jù)記錄器(熱電偶)打印輸出

the printout or chart from the autoclave從滅菌器打印或輸出圖表

the time the sterilisation period began and finished(per the data recorder time)滅菌周期起始和結(jié)束(根據(jù)數(shù)據(jù)記錄器的時間)

the time difference between the autoclave controller and the validation temperature monitoring device高壓滅菌柜控制器和溫度驗(yàn)證儀的時間差

the results of each BI and CI各生物指示劑和化學(xué)指示劑的結(jié)果

Label each document with the equipment ID,load description,date,test run number and cycle start/end time.

每個記錄分別標(biāo)明設(shè)備ID、負(fù)載說明、日期、測試編號和循環(huán)開始/結(jié)束時間。

If you fail to generate good documentation while conducting the validation test runs,you will not be able to analyse the data when putting together the report.Inadequate or poor quality data to support the validation process will not survive the scrutiny of an auditor.

如果在進(jìn)行驗(yàn)證測試運(yùn)行時未能生成良好的文檔,那么在編寫報(bào)告時就無法對數(shù)據(jù)進(jìn)行分析。支持驗(yàn)證過程的數(shù)據(jù)不充分或質(zhì)量差,將無法通過審計(jì)師的審查。

Tip:

提示

Be cautious about the acceptance criteria you employ to verify the accuracy of thermocouples.If the criterion is too tight(e.g.,all thermocouples must meet the acceptance criteria),you may lose a lot of runs if one or two thermocouples cease functioning or are outside the temperature tolerance after the runs.

對于驗(yàn)證熱電偶準(zhǔn)確性所采用的驗(yàn)收標(biāo)準(zhǔn)要謹(jǐn)慎。如果標(biāo)準(zhǔn)過于嚴(yán)格(例如,所有熱電偶都必須符合驗(yàn)收標(biāo)準(zhǔn)),那么在運(yùn)行后,如果有一兩個熱電偶停止工作或超出溫度公差范圍,您可能會損失大量運(yùn)行次數(shù)。

Consideration 8 The frequency of thermocouple accuracy verification

注意事項(xiàng)8:熱電偶精度驗(yàn)證頻率

If you are performing a large number of test runs(e.g.,over the course of several weeks),you need to think about the points at which you will verify the thermocouples'accuracy.This could be done after every run and/or at the end of the entire testing period.If you wait until the end of the testing period,you run the risk that all of the runs are of no value due to their failure to meet the verification acceptance criteria.Verifying after every run,however,adds considerably to the length of time required to complete the testing.Performing the verification every three runs or every few days is a reasonable compromise.

如果要進(jìn)行大量的測試運(yùn)行(例如,在幾個星期內(nèi)),則需要考慮驗(yàn)證熱電偶準(zhǔn)確性的時間點(diǎn)。這可以在每次運(yùn)行后和/或整個測試期結(jié)束時進(jìn)行。如果等到測試期結(jié)束后再進(jìn)行驗(yàn)證,就有可能出現(xiàn)所有運(yùn)行都因不符合驗(yàn)證驗(yàn)收標(biāo)準(zhǔn)而失去價值的情況。然而,在每次運(yùn)行后進(jìn)行驗(yàn)證會大大增加完成測試所需的時間。每三次運(yùn)行或每隔幾天進(jìn)行一次驗(yàn)證是一個合理的折中方案。

As noted in Consideration 6,the acceptance criterion you employ to verify the thermocouples'accuracy should allow at least one or two thermocouples to fail.

如考慮因素6所述,您用于驗(yàn)證熱電偶準(zhǔn)確性的驗(yàn)收標(biāo)準(zhǔn)應(yīng)允許至少有一個或兩個熱電偶失效。

Consideration 9 Having adequate time and access to the autoclave to complete the validation

注意事項(xiàng)9:有足夠的時間和途徑使用高壓滅菌器來完成驗(yàn)證

It’s easy to under estimate the length of time it takes to validate an autoclave,and how much access you need to it during the process.

我們很容易低估驗(yàn)證高壓滅菌器所需的時間,以及在驗(yàn)證過程中您需要接觸高壓滅菌器的程度。

For example,it can take up to four hours to set up your run,i.e.,prepare the load,place probes,BIs and CIs into the load,etc.If Production needs to use the autoclave and you need to remove your probes,BIs and CIs,then you need to start all over again,effectively losing a day.Work with the Production department when planning the Validation project to ensure that you have adequate access to the autoclave.

例如,設(shè)置運(yùn)行可能需要四個小時,即準(zhǔn)備負(fù)載、將探針、BI和CI放入負(fù)載等。如果生產(chǎn)部門需要使用高壓滅菌器,而您又需要移除探針、BI和CI,那么您就需要重新開始,這實(shí)際上會浪費(fèi)一天的時間。在規(guī)劃驗(yàn)證項(xiàng)目時,請與生產(chǎn)部門合作,以確保您有足夠的時間使用高壓滅菌器。

Another approach is to combine Phase II and III(Heat Distribution)with Phase IV(Heat Penetration)studies to save time.

另一種方法是將第二和第三階段(熱分布)與第四階段(熱滲透)研究結(jié)合起來,以節(jié)省時間。

Combining these three phases could reduce the time it takes to complete the validation project;however,you need to consider the following when doing this:

將這三個階段結(jié)合起來,可以減少完成驗(yàn)證項(xiàng)目所需的時間;但是,這樣做時需要考慮以下幾點(diǎn):

1 You will need to place probes into the chamber and into load items at the same time.Can you fit all the probes through the autoclave's inlet?If not,then you need to either validate each phase separately,or reduce the number of probes.

1、您需要將探針同時放入腔室和負(fù)載物品中。高壓滅菌器的入口是否能裝入所有探針?如果不能,則需要分別對每個階段進(jìn)行驗(yàn)證,或者減少探頭的數(shù)量。

2 Combining these three phases greatly increases your preparation time.If you are working on a tight schedule(e.g.,on a construction site where you need to evacuate at a certain time),you may not have time to complete the study.If this happens,then it may take more time to perform the work than if you had done each phase separately.

2、將這三個階段結(jié)合起來,可以大大增加準(zhǔn)備時間。如果您的工作時間很緊(例如,在建筑工地上,您需要在某個時間撤離),您可能沒有時間完成研究。如果出現(xiàn)這種情況,那么完成工作所需的時間可能會比分別完成每個階段所需的時間更長。

3 If you are under time pressure,there is a greater chance that you will miss something or make a mistake.

3、如果時間緊迫,您就更有可能遺漏或犯錯。

4 There are more data to consider.If you check only a few critical requirements before proceeding to the next study,you may miss something that did not meet an acceptance criterion.This may mean that all subsequent studies are at risk,because the data cannot be verified.For example,a probe may be falsely reading too high.

4、需要考慮的數(shù)據(jù)更多。如果在進(jìn)行下一項(xiàng)研究之前只檢查幾項(xiàng)關(guān)鍵要求,可能會遺漏一些不符合驗(yàn)收標(biāo)準(zhǔn)的數(shù)據(jù)。這可能意味著所有后續(xù)研究都有風(fēng)險(xiǎn),因?yàn)閿?shù)據(jù)無法驗(yàn)證。例如,探頭的讀數(shù)可能過高。

5 Allow enough time for the report to be completed.

5、準(zhǔn)備充足的時間來完成報(bào)告。

If you are validating a new autoclave,then you need to allow enough time for:

如果你是對新的高壓滅菌器進(jìn)行驗(yàn)證,那么你需要足夠的時間進(jìn)行:

(一)writing a validation plan

(一)編寫驗(yàn)證計(jì)劃

(二)writing the commissioning and IQ protocols

(二)編寫試機(jī)和IQ方案

(三)preparing the OQ/PQ protocols

(三)準(zhǔn)備OQ/PQ方案

(四)performing OQ/PQ studies

(四)開展OQ/PQ的研究

(五)writing the OQ/PQ reports,preparing folders,etc.

(五)編寫OQ/PQ的報(bào)告,準(zhǔn)備文件等

If you are performing a large number of test runs(e.g.,over the course of several weeks),then you need to ensure that enough time has been allocated to prepare the folders and write the reports.Allow one day to do a run and another day to analyse the data,i.e.,two days per study.Also allow time to write protocols and reports,and to have them reviewed and approved by other people(if appropriate).If you are developing the validation cycles,then this will also take time.

如果要進(jìn)行大量的測試運(yùn)行(例如,在幾周內(nèi)),則需要確保分配足夠的時間來準(zhǔn)備文件夾和撰寫報(bào)告。留出一天時間進(jìn)行測試,另一天時間分析數(shù)據(jù),即每項(xiàng)研究留出兩天時間。此外,還要留出時間來撰寫方案和報(bào)告,并由其他人(如適用)進(jìn)行審核和批準(zhǔn)。如果您正在制定驗(yàn)證周期,那么這也需要時間。

Consideration 10 Have the right procedural controls in place to ensure ongoing consistency and correct operation

注意事項(xiàng)10:制定正確的程序控制,確保持續(xù)的一致性和正確的操作

Congratulations,you have just finished validating a new autoclave for a number of different cycles and load configurations.Now,what controls need to be in place to ensure that the validated loads are used consistently?

恭喜您,您剛剛完成了對一臺新高壓滅菌器的多個不同周期和負(fù)載配置的驗(yàn)證。現(xiàn)在,需要采取哪些控制措施來確保一致地使用經(jīng)過驗(yàn)證的負(fù)載?

A Standard Operating Procedure(SOP)for the new autoclave should be prepared.It must include clear guidelines for each of the validated cycles,including diagrams of the load configurations.Test the procedure's clarity by asking a typical operator to follow the instructions with a dummy load.應(yīng)編制新高壓滅菌器的標(biāo)準(zhǔn)操作程序(SOP)。它必須包括每個驗(yàn)證周期的明確指南,包括負(fù)載配置圖。請一名典型的操作員使用假負(fù)載按照說明操作,以測試程序的清晰度。

Each operator who uses the autoclave should be trained and tested on the SOP.對每個使用高壓滅菌器操作者進(jìn)行培訓(xùn)和SOP考試。

Logbooks should be in place for each cycle.每個程序都應(yīng)有記錄。

Use a risk-based approach to determine the troubleshooting guidelines to include in the SOP.The manufacturer’s documentation and website may detail things that commonly go wrong.采用基于風(fēng)險(xiǎn)評估的方法制定檢修指南,包含在SOP里。制造商的文件和網(wǎng)站可能有常見故障的詳述。

An ongoing requalification program for the autoclave and the loads is required.The frequency can be 6,12 or 24 months.對于高壓滅菌器和裝載來說,持續(xù)再確認(rèn)程序是必需的,頻率可為6,12或24個月。

杭州美卓生物官網(wǎng)(www.dgwangming.com)所涉及的任何資料(包括但不限于文字、圖片、音頻、視頻、版面設(shè)計(jì))均受到《中華人民共和國著作權(quán)法》等法律法規(guī)保護(hù)。上述材料未經(jīng)許可,不得擅自進(jìn)行使用(復(fù)制、修改、轉(zhuǎn)載等)。如需轉(zhuǎn)載,必須取得杭州美卓生物的合法授權(quán)。如果已受本網(wǎng)授權(quán)使用,應(yīng)在授權(quán)范圍內(nèi)使用,并注明“來源:杭州美卓生物/美卓生物官網(wǎng)”。對于違反上述規(guī)定侵犯本網(wǎng)站知識產(chǎn)權(quán)等合法權(quán)益的行為,杭州美卓生物將依法追究其法律責(zé)任。

美卓設(shè)備

SPORIS??舒博消毒劑

解決方案

新聞資訊

資源支持

0571-86500029

18072756351

hzmeizhuo@163.com

杭州市濱江區(qū)西興街道楚天路270號1幢三樓

Copyrights?2012-2025 All Rights Reserved.杭州美卓生物科技有限公司

備案號:浙ICP備12034124號-1

備案號:浙ICP備12034124號-1

站點(diǎn)地圖 售后服務(wù) 友情鏈接:杭州美卓生物